GTACSR & GZTACSR Conductor

GTACSR & GZTACSR Conductor

HTLS GAP Conductor for Sale

GTACSR/AW & GZTACSR/AW

Application

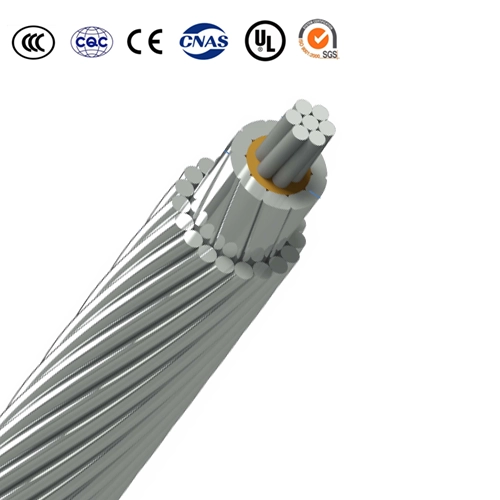

GTACSR & GZTACSR Conductor High Temperature Thermal Resistant Alloy Conductor : Aluminum-Zirconium wires (Type-AT1 or AT3), concentrically stranded over a steel core having a small gap between the Steel core & thermal-resistant aluminum alloy layer.

These combination offers best Mechanical as well as Electrical Characteristics. Extra High Strength Galvanized Steel (EST); or aluminum-claded Extra High Strength Steel (AW). Additional corrosion protection is achieved as High Temperature Grease is applied in Between GAP of Conductor.

Features:

• These can operate upto 210°C with specified strength loss

• Can carry 100~150% more current as that of ACSR of the same size

• For uprating lines, no modifications or reinforcement is required to the existing towers

• Limiting the sag increase with the increase of the temperature by the thermal expansion coefficient above knee-point related to the steel core

Specifications

Aluminium-Zirconium wires (Type-AT3 or AT-1), concentrically stranded over a steel core maintaing gap between the Steel core and first Aluminium Layer.

Values based on following Specifications:

• Thermal-resistant aluminium alloy wires (Type-AT3 or AT1) for overhead line conductor as per IEC 62004

• Concentric lay stranded overhead electrical conductors IEC 61089, IEC 62420

• Zinc-coated steel wires for stranded conductors IEC 888, ASTM B957 & more

• Zinc–5% Aluminum-Mischmetal Alloy-Coated Steel Core Wire EN 50540, ASTM B802, ASTM B803 or ASTM B958.

• Aluminium Clad Steel Wires, IEC 61232, ASTM B415, EN 50540 & More

Parameter

| Conductor Size | Stranding | Cross-Sectional Area | Diameter of Complete Conductor | Weight | Rated Strength | DCResistance @20°C | Current Capacity | ||||||||||

| No. of Wires | Wire diameter | TAL | Steel | Total | TAL | Steel | Total with Grease | Extra High Strength | Ultra High Strength | ||||||||

| TAL | Steel | TAL | Steel | @ 85°C | @ 150°C | @ 210°C | |||||||||||

| (mm²) | (No.) | (No.) | (mm) | (mm) | (mm²) | (mm²) | (mm²) | (mm) | (Kg/Km) | (Kg/Km) | (Kg/Km) | (KN) | (KN) | (Ω/Km) | (Ampere) | (Ampere) | (Ampere) |

| 175 | 8/12 | 7 | 3.35 (TW) | 2.10 | 176.20 | 24.25 | 200.45 | 17.50 | 486.98 | 189.44 | 691.42 | 66.14 | 66.87 | 0.1668 | 409 | 698 | 859 |

| 190 | 12/16 | 7 | 2.92 (TW) | 2.30 | 187.30 | 29.08 | 216.38 | 18.20 | 517.66 | 227.24 | 761.90 | 74.44 | 75.46 | 0.1569 | 425 | 728 | 896 |

| 195 | 20/12 | 7 | 2.40(R) 2.88(TW) | 2.20 | 168.80 | 26.61 | 195.41 | 18.06 | 466.53 | 207.91 | 690.44 | 69.51 | 70.31 | 0.1741 | 403 | 689 | 849 |

| 218 | 18/12 | 7 | 2.78(R) 2.94(TW) | 2.25 | 190.50 | 27.83 | 218.33 | 19.10 | 526.51 | 217.47 | 759.98 | 74.47 | 75.31 | 0.1542 | 433 | 744 | 917 |

| 240 | 8/12 | 7 | 4.02 (TW) | 2.40 | 253.40 | 31.67 | 285.07 | 20.60 | 700.35 | 247.43 | 964.78 | 88.34 | 89.45 | 0.1159 | 507 | 877 | 1083 |

| 248 | 12/8 | 7 | 3.71(TW) | 2.40 | 216.12 | 31.67 | 247.79 | 19.40 | 597.32 | 247.43 | 862.75 | 83.00 | 84.11 | 0.1360 | 463 | 796 | 981 |

| 287 | 18/12 | 7 | 3.15(R) 3.43(TW) | 2.55 | 251.00 | 35.75 | 286.75 | 21.77 | 693.72 | 279.33 | 993.04 | 94.85 | 96.10 | 0.1171 | 510 | 886 | 1096 |

| 287 | 20/12 | 7 | 2.90(R) 3.55(TW) | 2.55 | 251.00 | 35.75 | 286.75 | 21.77 | 693.72 | 279.33 | 993.04 | 95.33 | 96.58 | 0.1171 | 510 | 886 | 1096 |

| 310 | 16/12 | 7 | 3.90(R) 3.69(TW) | 2.80 | 319.40 | 43.10 | 362.50 | 24.40 | 882.76 | 336.78 | 1241.54 | 116.10 | 117.60 | 0.0920 | 589 | 1033 | 1281 |

| 400 | 18/12 | 7 | 3.90(R) 4.45(TW) | 2.80 | 401.40 | 43.10 | 444.50 | 26.90 | 1109.40 | 336.78 | 1468.18 | 129.16 | 130.67 | 0.0732 | 673 | 1190 | 1480 |

| 410 | 14/12 | 7 | 4.90(R) 3.99(TW) | 3.00 | 414.00 | 49.48 | 463.48 | 27.60 | 1144.22 | 386.61 | 1554.83 | 138.95 | 140.68 | 0.0710 | 687 | 1218 | 1515 |

| 439 | 15/12 | 7 | 4.50(R) 4.04(TW) | 2.90 | 392.50 | 46.24 | 438.74 | 26.84 | 1084.80 | 361.27 | 1469.07 | 132.44 | 134.06 | 0.0749 | 665 | 1176 | 1462 |

| 462 | 14/12 | 7 | 4.90(R) 3.99(TW) | 2.95 | 414.30 | 47.84 | 462.14 | 27.60 | 1145.05 | 373.83 | 1542.88 | 136.47 | 138.14 | 0.0709 | 687 | 1219 | 1516 |

| 540 | 24/14/10 | 7 | 3.55(R) 3.98(TW) | 3.10 | 536.20 | 52.83 | 589.03 | 31.30 | 1483.12 | 412.81 | 1920.93 | 164.15 | 166.00 | 0.0548 | 799 | 1436 | 1793 |

| 620 | 16/12/12 | 7 | 4.80(TW) 4.75(TW) 3.47(TW) | 3.20 | 615.70 | 56.30 | 672.00 | 31.50 | 1703.01 | 439.88 | 2168.89 | 177.96 | 179.93 | 0.0478 | 856 | 1539 | 1922 |

| Conductor Size | Cross-Sectional Area | Stranding | Diameter of Complete Conductor | Weight | Rated Strength | DC Resistance @20°C | Current Capacity | ||||||||||

| STAL | Steel | Total | No. of STAL Wires | No. of STAL Layers | No. of Steel Wires | Dia. of Steel Wires | STAL | Steel | Total | High Strength | Extra High Strength | ||||||

| @ 85°C | @ 150°C | @ 210°C | |||||||||||||||

| (mm²) | (mm²) | (mm²) | (mm²) | (No.) | (No.) | (No.) | (mm) | (mm) | (Kg/Km) | (Kg/Km) | (Kg/Km) | (KN) | (KN) | (Ω/Km) | (Ampere) | (Ampere) | (Ampere) |

| 175 | 8/12 | 7 | 3.35 (TW) | 2.10 | 176.20 | 24.25 | 200.45 | 17.50 | 486.98 | 160.46 | 647.44 | 57.65 | 62.26 | 0.1593 | 418 | 714 | 879 |

| 190 | 12/16 | 7 | 2.92 (TW) | 2.30 | 187.30 | 29.08 | 216.38 | 18.20 | 517.66 | 192.48 | 710.14 | 65.28 | 69.93 | 0.1490 | 436 | 747 | 919 |

| 195 | 20/12 | 7 | 2.40(R) 2.88(TW) | 2.20 | 168.80 | 26.61 | 195.41 | 18.06 | 466.53 | 176.11 | 642.64 | 60.20 | 65.25 | 0.1652 | 414 | 708 | 871 |

| 218 | 18/12 | 7 | 2.78(R) 2.94(TW) | 2.25 | 190.50 | 27.83 | 218.33 | 19.10 | 526.51 | 184.21 | 710.72 | 64.73 | 70.02 | 0.1470 | 444 | 762 | 940 |

| 240 | 8/12 | 7 | 4.02 (TW) | 2.40 | 253.40 | 31.67 | 285.07 | 20.60 | 700.35 | 209.59 | 909.94 | 78.36 | 83.43 | 0.1112 | 518 | 895 | 1105 |

| 248 | 12/8 | 7 | 3.71(TW) | 2.40 | 216.12 | 31.67 | 247.79 | 19.40 | 597.32 | 209.59 | 806.91 | 73.03 | 78.09 | 0.1295 | 474 | 816 | 1006 |

| 287 | 18/12 | 7 | 3.15(R) 3.43(TW) | 2.55 | 251.00 | 35.75 | 286.75 | 21.77 | 693.72 | 236.60 | 930.32 | 83.59 | 89.31 | 0.1117 | 523 | 908 | 1122 |

| 287 | 20/12 | 7 | 2.90(R) 3.55(TW) | 2.55 | 251.00 | 35.75 | 286.75 | 21.77 | 693.72 | 26.60 | 720.32 | 84.07 | 89.79 | 0.1117 | 523 | 908 | 1122 |

| 310 | 16/12 | 7 | 3.90(R) 3.69(TW) | 2.80 | 319.40 | 43.10 | 362.50 | 24.40 | 882.76 | 285.27 | 1168.03 | 102.52 | 109.41 | 0.0880 | 602 | 1056 | 1310 |

| 400 | 18/12 | 7 | 3.90(R) 4.45(TW) | 2.80 | 401.40 | 43.10 | 444.50 | 26.90 | 1109.40 | 285.27 | 1394.67 | 115.59 | 122.48 | 0.0706 | 685 | 1212 | 1507 |

| 410 | 14/12 | 7 | 4.90(R) 3.99(TW) | 3.00 | 414.00 | 49.48 | 463.48 | 27.60 | 1144.22 | 327.48 | 1471.70 | 123.36 | 131.28 | 0.0682 | 700 | 1242 | 1545 |

| 439 | 15/12 | 7 | 4.50(R) 4.04(TW) | 2.90 | 392.50 | 46.24 | 438.74 | 26.84 | 1084.80 | 306.00 | 1390.80 | 117.87 | 125.27 | 0.0720 | 678 | 1200 | 1491 |

| 462 | 14/12 | 7 | 4.90(R) 3.99(TW) | 2.95 | 414.30 | 47.84 | 462.14 | 27.60 | 1145.05 | 316.65 | 1461.70 | 121.40 | 129.05 | 0.0682 | 700 | 1242 | 1545 |

| 540 | 24/14/10 | 7 | 3.55(R) 3.98(TW) | 3.10 | 536.20 | 52.83 | 589.03 | 31.30 | 1483.12 | 349.67 | 1832.79 | 149.36 | 156.23 | 0.0536 | 808 | 1452 | 1812 |

| 620 | 16/12/12 | 7 | 4.80(TW) 4.75(TW) 3.47(TW) | 3.20 | 615.70 | 56.30 | 672.00 | 31.50 | 1703.01 | 372.60 | 2075.61 | 162.19 | 169.51 | 0.0467 | 865 | 1556 | 1944 |

PDF Download

PDF Download

Why Choose Us

Contact Us Immediately

Contact Us

- 24-hour online service

- Own factory processing

Product Category

hot-sale product

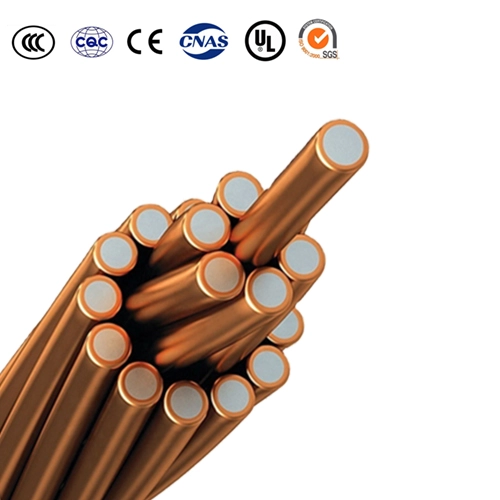

Dead Soft Annealed (DSA) Copper Clad steel (CCS) conductors are a concentric lay-stranded construction. The CCS strands are a 40% conductivity grade of material using a low carbon steel core rendering greater flexibility to enable easier handling during installation.

Bare Overhead Transmission Conductor

Distribution Conductor and Messenger Support

Steel Core Aluminum Alloy Stranded Wire

Bare Overhead Transmission Conductor

Distribution Conductor and Messenger Support

Steel Core Aluminum Alloy Stranded Wire

Bare Overhead Conductor

AAAC Bare Aluminum Conductor

AAAC Aerial Conductors

Overhead Line Conductors

Manufacturer & Supplier from China

Our reputation is based on providing the sophisticated products and thoughtful services to ourcustomers, which makes us unique among cable manufacturers.

Follow Us:

products

Inquiry

© Copyright 2023 by Henan Shuobang Cable Co., Ltd. All Rights Reserved.