CCS-Copper Clad Steel Strand

CCS-Copper Clad Steel Strand

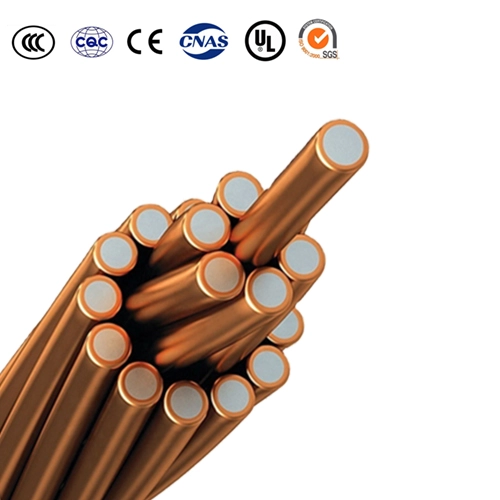

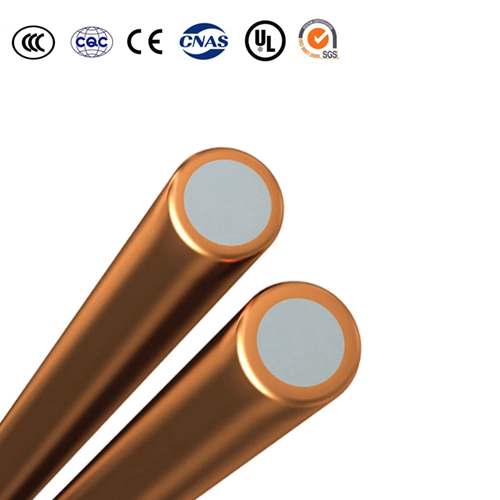

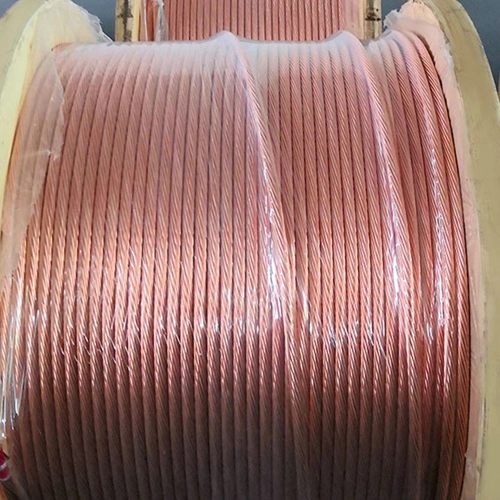

Dead Soft Annealed (DSA) Copper Clad steel (CCS) conductors are a concentric lay-stranded construction. The CCS strands are a 40% conductivity grade of material using a low carbon steel core rendering greater flexibility to enable easier handling during installation.

Application

Copper clad steel wire (CCS Wire) combines the high tensile strength of steel as its core and the conductivity properties of copper as its outer layer. The core material is usually low carbon steel and is typically used as either grounding wire or the inner conductor of coaxial cables.

DSA Copper Clad Steel stranded conductors are used in place of copper conductors in grounding applications and systems.conductors are classified as follows: Grade 40 HS, Grade 30 HS, Grade 30 EHS, Grade 40 DSA, and Grade 30 DSA.CCS strand wire is divided into soft state and hard state with perfect conductivity, which is a good choice for various industries such as communications, electrical power and electronics.

Specifications

● ASTM B 228 Concentric-Lay-Stranded Copper-Clad Steel Conductors

Parameter

| CCS(Conductivity 20.3)Size Designation | Conductor Area |

No.of Wires | Diameter mm |

Min.Rated Breaking Strength kN |

Weight kg/km |

Max.D.C. Resistance at 20℃ Ω/km |

|||

| AWG | mm² | in² | Wire | Cond. | Grade 40 HS |

Grade 40 DSA |

Grade 40 | ||

| 19 No.5 | 318.71 | 0.4940 | 19 | 4.620 | 23.11 | 216.66 | 76.68 | 2660.8 | 0.14423 |

| 19 No.6 | 252.71 | 0.3917 | 19 | 4.115 | 20.57 | 179.45 | 60.81 | 2110.2 | 0.18183 |

| 19 No.7 | 200.45 | 0.3107 | 19 | 3.665 | 18.31 | 148.29 | 48.23 | 1674.2 | 0.22937 |

| 19 No. 8 | 158.97 | 0.2464 | 19 | 3.264 | 16.31 | 122.46 | 38.27 | 1327.4 | 0.28896 |

| 19 No. 9 | 126.06 | 0.1954 | 19 | 2.906 | 14.53 | 100.86 | 30.33 | 1052.6 | 0.36452 |

| 7 No. 4 | 148.06 | 0.2295 | 7 | 5.189 | 15.57 | 96.15 | 35.61 | 1231.5 | 0.30930 |

| 7 No. 5 | 117.42 | 0.1820 | 7 | 4.620 | 13.87 | 79.84 | 28.25 | 976.5 | 0.38978 |

| 7 No. 6 | 93.10 | 0.1443 | 7 | 4.115 | 12.34 | 66.10 | 22.41 | 774.3 | 0.4915 |

| 7 No.7 | 73.87 | 0.1145 | 7 | 3.665 | 11.00 | 54.63 | 17.76 | 614.5 | 0.6201 |

| 7 No. 8 | 58.56 | 0.09077 | 7 | 3.264 | 9.78 | 45.12 | 14.10 | 487.1 | 0.7812 |

| 7 No. 9 | 46.44 | 0.07198 | 7 | 2.906 | 8.71 | 37.16 | 11.18 | 386.2 | 0.9859 |

| 7 No. 10 | 36.83 | 0.05708 | 7 | 2.588 | 7.77 | 30.73 | 8.87 | 306.3 | 1.2422 |

| 3 No. 5 | 50.32 | 0.07800 | 3 | 4.620 | 9.96 | 36.10 | 12.78 | 417.7 | 0.9082 |

| 3 No. 6 | 39.90 | 0.06185 | 3 | 4.115 | 8.86 | 29.91 | 10.14 | 331.3 | 1.1447 |

| 3 No. 7 | 31.65 | 0.04905 | 3 | 3.665 | 7.90 | 24.71 | 8.04 | 262.7 | 1.4440 |

| 3 N0. 8 | 25.10 | 0.03890 | 3 | 3.264 | 7.04 | 20.41 | 6.38 | 208.3 | 1.8193 |

| 3 No. 9 | 19.90 | 0.03085 | 3 | 2.906 | 6.27 | 16.81 | 5.05 | 165.2 | 2.2957 |

| 3 No. 10 | 15.78 | 0.02446 | 3 | 2.588 | 5.59 | 13.90 | 4.01 | 131.0 | 2.8929 |

| 3 No. 12 | 9.93 | 0.01539 | 3 | 2.052 | 4.42 | 7.32 | 2.55 | 82.4 | 4.5573 |

| Size Designation | Conductor Area |

No.of wires | Diameter mm |

Min.Rated Breaking Strength kN | Weight kg/km |

Max. Resistance at 20℃ Ω/km |

||||

| AWG | mm² | in² | Wire | Cond. | Grade 30HS | Grade 30 EHS | Grade 30 DSA | Grade 30 | ||

| 19 No.5 | 318.71 | 0.4940 | 19 | 4.620 | 23.11 | 239.64 | 288.54 | 86.28 | 2634.0 | 0.19227 |

| 19 No.6 | 252.71 | 0.3917 | 19 | 4.115 | 20.57 | 197.68 | 239.51 | 68.41 | 2087.9 | 0.24240 |

| 19 No.7 | 200.45 | 0.3107 | 19 | 3.665 | 18.31 | 162.74 | 197.72 | 54.23 | 1656.3 | 0.30576 |

| 19 No. 8 | 158.97 | 0.2464 | 19 | 3.264 | 16.31 | 133.98 | 162.65 | 43.06 | 1313.6 | 0.3852 |

| 19 No. 9 | 126.06 | 0.1954 | 19 | 2.906 | 14.53 | 109.93 | 132.02 | 34.12 | 1041.7 | 0.4862 |

| 7 No. 4 | 148.06 | 0.2295 | 7 | 5.189 | 15.57 | 106.86 | 126.87 | 40.07 | 1218.7 | 0.4124 |

| 7 No. 5 | 117.42 | 0.1820 | 7 | 4.620 | 13.87 | 88.28 | 106.28 | 31.78 | 966.4 | 0.5197 |

| 7 No. 6 | 93.10 | 0.1443 | 7 | 4.115 | 12.34 | 72.86 | 88.24 | 25.21 | 766.3 | 0.6552 |

| 7 No.7 | 73.87 | 0.1145 | 7 | 3.665 | 11.00 | 59.97 | 72.86 | 19.99 | 608.1 | 0.8268 |

| 7 No. 8 | 58.56 | 0.09077 | 7 | 3.264 | 9.78 | 49.34 | 59.92 | 15.86 | 482.0 | 1.0414 |

| 7 No. 9 | 46.44 | 0.07198 | 7 | 2.906 | 8.71 | 40.51 | 48.63 | 12.57 | 382.2 | 1.3144 |

| 7 No. 10 | 36.83 | 0.05708 | 7 | 2.588 | 7.77 | 33.48 | 39.69 | 9.97 | 303.1 | 1.6559 |

| 3 No. 5 | 50.32 | 0.07800 | 3 | 4.620 | 9.96 | 39.94 | 48.10 | 14.38 | 413.4 | 1.2104 |

| 3 No. 6 | 39.90 | 0.06185 | 3 | 4.115 | 8.86 | 32.95 | 39.92 | 11.41 | 327.8 | 1.5260 |

| 3 No. 7 | 31.65 | 0.04905 | 3 | 3.665 | 7.90 | 27.12 | 32.95 | 9.04 | 260.0 | 1.9250 |

| 3 N0. 8 | 25.10 | 0.03890 | 3 | 3.264 | 7.04 | 22.33 | 27.11 | 7.17 | 206.1 | 2.4253 |

| 3 No. 9 | 19.90 | 0.03085 | 3 | 2.906 | 6.27 | 18.32 | 22.00 | 5.69 | 163.5 | 3.0605 |

| 3 No. 10 | 15.78 | 0.02446 | 3 | 2.588 | 5.59 | 15.14 | 17.95 | 4.51 | 129.6 | 3.855 |

| 3 No. 12 | 9.93 | 0.01539 | 3 | 2.052 | 4.42 | 7.64 | 11.40 | 2.87 | 81.6 | 6.073 |

PDF Download

PDF Download

Why Choose Us

Contact Us Immediately

Contact Us

- 24-hour online service

- Own factory processing

Product Category

hot-sale product

ACS Wire Manufacturers

Aluminium Clad Wire (ACS) Manufacturer

ACSS ACSS/AW ACSS/TW Conductor

SHAPED WIRE ALUMINUM CONDUCTOR

- Steel part: Aluminum-clad steel wires (AW).

- Aluminium part: Thermal resistant aluminum alloy wires (TAL), concentric stranded.

- Grease part: Neutral grease (G), this is optional part in accordance with IEC 61089.

Used for overhead power transmission lines

Core Wire (INVAR) : Aluminum-clad INVAR Wire/High Tensile Strength Aluminum-clad INVAR Wire

Conductor (STAL) : Super Thermal Resistant Aluminum Alloy Wire used for continuous allowable temperature up to 210°C

Our reputation is based on providing the sophisticated products and thoughtful services to ourcustomers, which makes us unique among cable manufacturers.

Follow Us:

products

Inquiry

© Copyright 2023 by Henan Shuobang Cable Co., Ltd. All Rights Reserved.