TACSR/AW Thermal-Resistant Aluminum Alloy Conductor Aluminum Clad Steel Reinforced

TACSR/AW Thermal-Resistant Aluminum Alloy Conductor Aluminum Clad Steel Reinforced

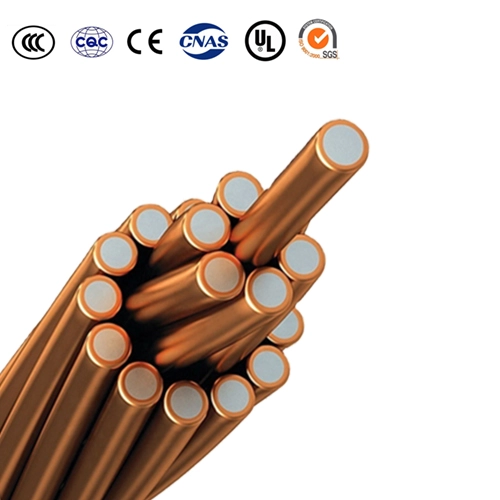

- Steel part: Aluminum-clad steel wires (AW).

- Aluminium part: Thermal resistant aluminum alloy wires (TAL), concentric stranded.

- Grease part: Neutral grease (G), this is optional part in accordance with IEC 61089.

Application

TACSR/AW Thermal-Resistant Aluminum alloy conductor ,aluminum clad steel reinforced is a high ampacity conductor with inner core composed of Aluminum clad Steel & outer layer composed of thermal resistant aluminium alloy with round.

Thermal-Resistant Aluminum alloy conductor aluminum clad steel reinforced is used for overhead transmission line, ground line, electric railway. Due to its obvious advantage of anti-corrosion and high strength, it is applicable for long- span line, severe cold zone with heavy snow and other bad weather besides general transmission line.Used for power plant, power transmission and distribution line, the voltage ranges from 1 kV to 750 kV, especially used in compacity – expansion route and transformation of the old lines.

Specifications

● IEC 61089 Round Wire Concentric Lay Overhead Electrical Stranded Conductors

● IEC 62004 Thermal -Resistant Aluminum Alloy Wires For Overhead Line Conductor

● NB/T 42060 Thermal -Resistant Aluminum Alloy Conductors, Steel Core Reinforced For Overhead Transmission Line

Parameter

| JNRLH1 / LB20A

Nominal Area |

No. of Wires | Diameter | Area | Diameter | Linear Mass |

Rated Strength | DC. Resistance at 20℃ | ||||

| TAL | St | TAL | St | TAL | St | Total | JNRLH1/ LB20A |

||||

| mm² | No. | mm | mm² | mm | kg/km | kN | Ω/km | ||||

| 300/40 | 24 | 7 | 3.99 | 2.66 | 300.1 | 38.9 | 339.0 | 23.9 | 1085.5 | 94.39 | 0.0936 |

| 300/50 | 26 | 7 | 3.83 | 2.98 | 299.5 | 48.8 | 348.3 | 24.3 | 1150.3 | 106.2 | 0.0928 |

| 400/35 | 48 | 7 | 3.22 | 2.5 | 390.9 | 34.4 | 425.3 | 26.8 | 1307.6 | 104.6 | 0.0729 |

| 400/50 | 54 | 7 | 3.07 | 3.07 | 399.7 | 51.8 | 451.5 | 27.6 | 1448.6 | 126.9 | 0.0704 |

| 400/65 | 26 | 7 | 4.42 | 3.44 | 398.9 | 65.1 | 464.0 | 28.0 | 1532.2 | 140.2 | 0.0697 |

| 500/35 | 45 | 7 | 3.76 | 2.51 | 499.7 | 34.6 | 534.3 | 30.1 | 1609.9 | 122.5 | 0.0574 |

| 500/45 | 48 | 7 | 3.6 | 2.8 | 488.6 | 43.1 | 531.7 | 30.0 | 1635.5 | 130.9 | 0.0584 |

| 630/45 | 45 | 7 | 4.22 | 2.81 | 629.4 | 43.4 | 672.8 | 33.8 | 2026.5 | 152.2 | 0.0456 |

| 630/55 | 48 | 7 | 4.12 | 3.2 | 639.9 | 56.3 | 696.2 | 34.3 | 2141 | 169.3 | 0.0446 |

| 720/50 | 45 | 7 | 4.53 | 3.02 | 725.3 | 50.1 | 775.4 | 36.2 | 2336 | 175.5 | 0.0396 |

| 800/55 | 45 | 7 | 4.8 | 3.2 | 814.3 | 56.3 | 870.6 | 38.4 | 2622.7 | 197.0 | 0.0352 |

| JNRLH1 / LB14

Nominal Area |

No. of Wires | Diameter | Area | Diameter | Linear Mass |

Rated Strength | DC. Resistance at 20℃ | ||||

| TAL | St | TAL | St | TAL | St | Total | JNRLH1/ LB14 |

||||

| mm² | No. | mm | mm² | mm | kg/km | kN | Ω/km | ||||

| 300/40 | 24 | 7 | 3.99 | 2.66 | 300.1 | 38.9 | 339 | 23.9 | 1106.9 | 102.6 | 0.0948 |

| 300/50 | 26 | 7 | 3.83 | 2.98 | 299.5 | 48.8 | 348.3 | 24.3 | 1177.2 | 116.5 | 0.0944 |

| 400/35 | 48 | 7 | 3.22 | 2.5 | 390.9 | 34.4 | 425.3 | 26.8 | 1326.6 | 111.8 | 0.0736 |

| 400/50 | 54 | 7 | 3.07 | 3.07 | 399.7 | 51.8 | 451.5 | 27.6 | 1477.2 | 136.3 | 0.0714 |

| 400/65 | 26 | 7 | 4.42 | 3.44 | 398.9 | 65.1 | 464 | 28 | 1568.1 | 153.2 | 0.0708 |

| 500/35 | 45 | 7 | 3.76 | 2.51 | 499.7 | 34.6 | 534.3 | 30.1 | 1629.1 | 129.8 | 0.0578 |

| 500/45 | 48 | 7 | 3.6 | 2.8 | 488.6 | 43.1 | 531.7 | 30 | 1659.3 | 139.9 | 0.0589 |

| 630/45 | 45 | 7 | 4.22 | 2.81 | 629.4 | 43.4 | 672.8 | 33.8 | 2050.5 | 161.3 | 0.0459 |

| 630/55 | 48 | 7 | 4.12 | 3.2 | 639.9 | 56.3 | 696.2 | 34.3 | 2172.1 | 179.4 | 0.045 |

| 720/50 | 45 | 7 | 4.53 | 3.02 | 725.3 | 50.1 | 775.4 | 36.2 | 2363.7 | 184.5 | 0.0398 |

| 800/55 | 45 | 7 | 4.8 | 3.2 | 814.3 | 56.3 | 870.6 | 38.4 | 2653.8 | 207.2 | 0.0355 |

| Nominal Area | No. of Wires | Diameter | Area | Diameter | Linear Mass |

Rated Strength | DC. Resistance at 20℃ | ||||

| TAL | St | TAL | St | TAL | St | Total | |||||

| mm² | No. | mm | mm² | mm | kg/km | kN | Ω/km | ||||

| 160 | 30 | 7 | 2.6 | 2.6 | 159 | 37.2 | 196.2 | 18.20 | 686 | 68.4 | 0.171 |

| 240 | 30 | 7 | 3.2 | 3.2 | 241 | 56.3 | 297.3 | 22.40 | 1024 | 99.5 | 0.112 |

| 330 | 26 | 7 | 4.0 | 3.1 | 327 | 52.8 | 379.8 | 25.30 | 1252 | 107.2 | 0.085 |

| 410 | 26 | 7 | 4.5 | 3.5 | 414 | 67.3 | 481.3 | 28.50 | 1569 | 136.1 | 0.0671 |

| 520 | 54 | 7 | 3.5 | 3.5 | 520 | 67.3 | 587.3 | 31.50 | 1881 | 153.0 | 0.0567 |

| 610 | 54 | 7 | 3.8 | 3.8 | 612 | 79.4 | 691.4 | 34.20 | 2219 | 180.0 | 0.0458 |

| 680 | 45 | 7 | 4.4 | 2.9 | 684 | 46.2 | 730.2 | 35.10 | 2201 | 152.9 | 0.0421 |

| 810 | 45 | 7 | 4.8 | 3.2 | 814 | 56.3 | 870.3 | 38.40 | 2627 | 180.9 | 0.0353 |

| 1160 | 84 | 7 | 4.2 | 4.2 | 1164 | 97.0 | 1261.0 | 46.20 | 3873 | 273.8 | 0.0246 |

| 1520 | 84 | 7 | 4.8 | 4.8 | 1520 | 126.7 | 1646.7 | 52.80 | 5058 | 357.8 | 0.0190 |

PDF Download

PDF Download

Why Choose Us

Contact Us Immediately

Contact Us

- 24-hour online service

- Own factory processing

Product Category

hot-sale product

570-AL4 ASTER 570 Cable Almelec

Conductors in aluminium alloy (AAAC)

Cable Almelec 148 mm2

Cable Almelec 34.4 mm2

Cable Almelec 93 mm2

Cable Almelec 54.6 mm2

Cable Almelec 570 mm2

Dead Soft Annealed (DSA) Copper Clad steel (CCS) conductors are a concentric lay-stranded construction. The CCS strands are a 40% conductivity grade of material using a low carbon steel core rendering greater flexibility to enable easier handling during installation.

Aluminum Conductor, Steel Supported. Bare.

Aluminum Overhead Transmission & Distribution

TAAAC or TAL Conductor

High Temperature Conductor

Our reputation is based on providing the sophisticated products and thoughtful services to ourcustomers, which makes us unique among cable manufacturers.

Follow Us:

products

Inquiry

© Copyright 2023 by Henan Shuobang Cable Co., Ltd. All Rights Reserved.